ABSTRACT

This assignment presents a literature review of quality

function deployment (QFD) based on a reference QFD publications established

through searching various sources. The origination and historical development

of QFD, especially in Japan and the US, are briefly accounted first, followed

by a partial list of QFD organizations, software, and online resources. Then a

categorical analysis is conducted about QFD’s functional fields, applied

industries and methodological development. Ten informative QFD publications are

also suggested, particularly for those who are not yet familiar with QFD. It is

hoped that the assignment can serve the needs of researchers and practitioners

for easy references of QFD studies and applications, and hence promote QFD’s

future development.

Keywords;

Quality management; Product development; Customer

needs; Quality function deployment (QFD)

1. INTRODUCTION

Quality function deployment (QFD) is “an overall concept

that provides a means of translating customer requirements into the appropriate

technical requirements for each stage of product development and production

(example in; marketing strategies, planning, product design and engineering,

prototype evaluation, production process development, production, sales)” (Sullivan,

1986). Since its initial development in Japan in the late 1960s and early

1970s, especially since its rapidly spreading to the US in the 1980s and later

to many industries in many nations, a vast literature on QFD has evolved. To

suit the different needs of QFD researchers and practitioners, its literature

needs categorizing and reviewing. This is a meaningful but difficult work that

seems having not been done yet.Although our literature search is admittedly

incomplete, we believe that it covers a reasonable portion of QFD publications

and thus is a useful source for QFD researchers and practitioners.

In this assignment, we try to conduct a literature review of

QFD based on the above-mentioned reference. We first give a brief historical

review of QFD with emphases on its origination and its development in Japan. A

number of QFD organizations, software, and online resources are also listed for

references. Then we present a categorical analysis of QFD applications in terms

of purposes and where it has been applied to industries. We then proceed to

review the methodological development of QFD, including quantitative methods

applicable to it and its extensions and implementation issues. It is hoped that

this assignment can serve the needs of interested readers for references of QFD

studies and applications, and hence promote the future development of QFD.

2. A BRIEF REVIEW OF

QFD’S HISTORY

2.1. Origination of

QFD

In the Foreword for J. Terninko’s book Step by Step QFD (Terninko,

1997), B. King wrote,

“In the 1960s, Quality Control and Quality Improvement had a

distinctively manufacturing flavor in Japan. In the late 1960s and early 1970s,

Joji, (Yoji)Akao and others went to work on improving the design process so

that when the new product was introduced to manufacturing, it was high quality

from the beginning. The process for improving design was called Quality

Function Deployment (QFD). From 1975 to 1995, this tool (process) was

integrated with other improvement tools to generate a mosaic of opportunities

for product developers.”

In Chapter 21, Quality Function Deployment, of the second

edition of Gower Handbook of Quality Management edited by D. Lock, (Hill

1994) wrote similarly,

“QFD evolved from a number of different initiatives between

1967 and 1972, but the two main drivers which led to its creation in Japan were

those:”

To improve the ‘quality of design’.

To provide manufacturing and field staff with the planned

quality control chart (showing the points to be controlled within the

production process) before the initial production run.”

Therefore, it is clear that “it was the struggle by product

designers under the total quality control movement to improve their work that

spawned quality function deployment in Japan” (Neff, 1991).

2.2. Development of

QFD in Japan

Historically, Japanese industry began to formalize the QFD

concepts when Mr. Oshiumi of the Kurume Mant plant of Bridgestone Tire produced

a processing assurance chart containing some of QFD’s main characteristics in

1966 and K. Ishihara developed the ideas of “functional deployment of business”

similar to those of QFD and applied them to Matsushita in the late 1960s (Cohen,

1995; Hill, 1994; Marsh et al., 1991).However, it was Akao who first

realized the value of this approach in 1969 and wanted to utilize its power

during the product design stage so that the product design characteristics

could be converted into precise quality control points in the manufacturing

quality control chart (Hill, 1994).After several industrial trials, Akao wrote

a paper on this new approach in 1972 and called it hinshitsutenkai (quality

deployment). This paper and Nishimura (1972) were the first two

papers fostering the then new concept of QFD known to the West.

In the meantime, the Kobe Dockyard of Mitsubishi Heavy

Industries began to apply the ideas of QFD in 1971 following Akao’s suggestion (Pardee,

1996),and Nishimura at Kobe produced a quality table that showed the

correlation between the customer-required quality functions and the counterpart

engineering characteristics between 1972 and 1974 (Hill, 1994; Nishimura,

1972).Akao formulated all these into a procedure channeling the customer

requirements from the design stages down to the production operations, which

was calledhinshitsukinotenkai (quality function deployment) (Cohen, 1995; Hauser

and Clausing, 1988; Hill, 1994;Marsh et al., 1991; Prasad, 1998; Sullivan,

1986). QFD was introduced to Toyota’s Hino Motor in 1975

and Toyota Auto body in 1977 with impressive results, and was later introduced

into the whole Toyota group.

A Japanese book on QFD edited by Mizuno and Akao, Deployment

of the Quality Function, was published in 1978, showing the fast development

and wide applications of QFD in Japan. Two years later, Kayaba won the Deming

Prize with special recognition for applying QFD to bottleneck engineering (Cohen,

1995; Marsh et al., 1991).

Through the above-described explorations and practices, QFD

has been successfully used in many Japanese industries, such as agriculture

systems, construction equipment, consumer electronics, home appliances,

integrated circuits, software systems, steel, synthetic rubber, and textile.

3. FUNCTIONAL FIELDS

OF QFD

QFD was originally proposed, through collecting and

analyzing the voice of the customer, to develop products with higher quality to

meet or surpass customer’s needs. There are many approaches to QFD. Almost everyone

agrees that for QFD to be successfully implemented within an organization. One

of the approaches called The Four (4)-Phase approach.

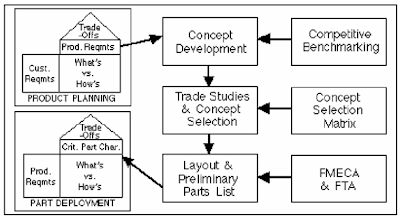

QFD methodology flow: 4-Phase Approach

Product Planning

Part Deployment

Process Planning

Process/ Quality Control

4. FOUR (4) - PHASE

APPROACH AND HOUSE OF QUALITY

A four phase approach is accomplished by using a series of

matrices. Each phase has a matrix consisting of a vertical column of “Whats”

and a horizontal row of “Hows”. Both legends of column and rows shows that

“Whats” are Customer Requirements, meanwhile “Hows” are ways of achieving them.At

each stage, the “Hows” are carried to the next phase as “Whats”

Figure 1: House of

Quality Series

1ST PHASE: PRODUCT

PLANNING

HOUSE OF QUALITY

The first phase in

the implementation of the Quality Function Deployment process involves putting

together a "House of Quality" (Hauser and Clausing, 1988) such as the

one shown below, which is for the development of a climbing harness (fig. from Lowe

& Ridgway, 2001).

Figure 2: Expanded House of Quality: Terminology and Conventions

The first step in a QFD project is to determine

what market segments will be analyzed during the process and to identify who

the customers are. The team then gathers information from customers on the

requirements they have for the product or service. In order to organize and

evaluate this data, the team uses simple quality tools like Affinity Diagrams

or Tree Diagrams.

Figure 4: Affinity Diagrams

Table 1: Quantify Table Requirements

Table 2: Planning Matrix

Table 3: Planning Matrix

TECHNICAL REQUIREMENTS

Table 4: Technical Requirements

Table 5: Interrelationships

Use symbols for strong, medium, weak and none

relationships.

The goal is to determine the relative positions of existing products with regard to each of the identified technical requirements

Figure 4: Affinity Diagrams

Quantify Customer Requirements

Not all product or service

requirements are known to the customer, so the team must document requirements

that are dictated by management or regulatory standards that the product must

adhere to.

Table 1: Quantify Table Requirements

PLANNING MATRIX

Evaluate your planned product against competitive

products.

Consider the current strengths and weaknesses against your

competitors.

Identify in what

areas the competitors are better, equal or worse at.

Identify what should

be done to the product to reach expectations.

Table 2: Planning Matrix

• Customer Satisfaction.

Existing products fulfilling specified requirements.

• Improvement Ratio = Planned Performance / Existing

Performance

• Sales Point

Weight for marketability.

• Overall Weighting = (Importance Weighting) x (Improvement

Ratio) X(Sales Point).

Table 3: Planning Matrix

TECHNICAL REQUIREMENTS

To better understand the

competition, engineering then conducts a comparison of competitor technical

descriptors. This process involves reverse engineering competitor products to

determine specific values for competitor technical descriptors.

Identify Measurable

Characteristics relate to Customer Requirements.

It may have more than

one technical requirement to convey one customer requirement.

Table 4: Technical Requirements

INTERRELATIONSHIPS

Develop relationships between all

customer requirements and product requirements.

Critical Question:

How significant is technical

requirement A in satisfying customer requirement B?

Are there product requirements that don't relate

to any customer needs?Table 5: Interrelationships

THE ROOF

Considers impact of technical requirements on each other

Feature to feature

comparison.

Critical Question:

Does improving one requirement cause a deterioration or

improvement in another requirement?

TARGETS

Develop preliminary target values for product requirements

Analyze the matrix and finalize the product development

strategy and product plans.

Results from previous steps:

Customer requirements

Prioritized customer requirements

Technical requirements

Correlated requirements

Feature interdependencies

Made up from three parts:

Technical priorities

Competitive benchmarks

Final Product Targets

Calculate technical priorities

Assign a weighting factor to relationship symbols

Multiply each interrelationship weighting by the overall

weighting from the planning matrix.

Sum them to their

own columns.

Table 6: Calculate

Technical Priorities

Competitive Benchmarks

Matrix values are simply the measure of the

technical requirement.The goal is to determine the relative positions of existing products with regard to each of the identified technical requirements

Table 7: Competitive

Benchmarks

Final Product Targets

Analyze the matrix

and finalize the product development strategy and product plans.

Table 8: Final

Product Targets

HOUSE OF QUALITY

Figure 6: House of

Quality

HOUSE OF QUALITY

SUMMARY

Inputs:

Customer requirements

Technical requirements

Customer priorities

Market reality / competitive analysis

Organization’ s strengths & weaknesses

Outputs

Prioritized technical requirements

Measurable, testable goals

The main difference with the subsequent phases however, is

that in Phase 2 the process becomes a translation of the voice of the engineer

in to the voice of the part design specifications.

Then, in phase 3, the part design specifications get

translated into the voice of manufacturing planning. And finally, in phase 4,

the voice of manufacturing is translated into the voice of production planning.

SECOND PHASE: PART DEPLOYMENT

The product requirements or technical characteristics and

the product specification serve as the basis for developing product concepts.

Product benchmarking, brainstorming, and research and

development are sources for new product concepts.

Once concepts are developed, they are analyzed

and evaluated (cost & trade) using the concept selection matrix.

Table

9: Product Benchmarking

Using the selected concept

as a basis, develop a design layout, block diagram and/or a preliminary parts

list. Determine critical subsystems, sub assemblies or parts.

Figure 7: Design Layout

Analyze the matrix and finalize the

subsystem/subassembly/part deployment matrix. Determine required actions and

areas of focus.

Finalize

target values. Consider interactions, importance ratings and difficulty

ratings.

Table 10: Finalize Values

THIRD PHASE: PROCESS PLANNING

Concept selection matrix can be used to evaluate different

manufacturing process approaches and select the preferred approach.

Based on selected approach, the process planning matrix is

prepared.

Important processes

and tooling requirements can be identified to focus efforts to control, improve

and upgrade processes and equipment

Table 11: Concept Selection Matrix

FOURTH PHASE: PROCESS / QUALITY CONTROL

Detailed planning related to process control, quality

control, set -up, equipment maintenance and testing can be supported by

process/quality control matrix.

The process steps developed in the process

planning matrix are used as the basis for planning and defining specific

process and quality control steps in this matrix.

Table 12: Process

Planning Matrix

5. THE FOUR (4) –

PHASE OF TRADITIONAL QFD

Figure 8: Phase of Traditional QFD

6. BENEFITS OF USING QFD

Products meet customer expectations better.

Improved design traceability.

Reduced lead times.

Reduced product cost.

Improved communication within organization and with customer

7. PROBLEMS AND DISADVANTAGES

When applying QFD do not underestimate the amount of work

involved.

Extra time and resources early in the project. Management

must be prepared for this, and not press for visible results too early.

The scope and objectives of the project must be agreed at

the beginning.

Avoid trying to include too much detail. Too large a matrix

results in too much data to analyze.

Avoid gathering perfect data. Avoid technical arrogance and

the belief that company personnel know more than the customer.

Best results are usually obtained by using an

independent QFD facilitator to control the QFD process, leaving the rest of the

team free to concentrate on the product.

8. SUMMARY OF TOPIC

QFD is a systematic means of ensuring that customer

requirements are accurately translated into relevant technical descriptors

throughout each stage of product development.

Therefore, meeting or exceeding customer demands means more than just

maintaining or improving product performance.

It means designing and manufacturing products that delight customers and

fulfill their unarticulated desires.

Companies growing into the 21st century will be enterprises that foster

the needed innovation to create new markets. Therefore, we can conclude QFD is:

Understanding customer requirements.

Quality systems thinking

+ Psychology + Knowledge/Epistemology.

Maximizing Positive Quality That Ads Value.

Comprehensive Quality System forCustomer Satisfaction.

Strategy to Stay Ahead of The Game

Finally, since tool

is make to just

aid people, even

the most fully functional

and powerful QFD software cannot replace a bit of any creativity and

team works. So the best strategy should be: take advantages of best minds

first, then the best software.

9. REFERENCES

Bester Field, D.H. Total Quality Management, 2nd Ed. Upper

Saddle River, New Jersey, Prentice Hall,

(1999)

Akao, Y., Ed. (1990). Quality Function Deployment, Productivity

Press, Cambridge MA.

Hauser, J. R. and D. Clausing (1988). "The House of

Quality," The Harvard Business Review.

Mizuno, S. and Y. Akao, ed. (1994). QFD: The Customer-Driven

Approach to Quality Planning

Adams and Gavoor, (1990) R.M Adams, M.D GavoorQuality

function deployment: Its promise and

reality Transactions of the 1990 ASQC Quality Congress, San Francisco, CA

(1990), pp. 33–38

Becker Associates Inc, http://www.becker-associates.com/thehouse.HTM

and http://www.becker-associates.com/qfdwhatis.htm

Lowe, A.J. & Ridgway, K. Quality Function Deployment,

University of Sheffield, and Development,

Asian Productivity Organization, Tokyo, Japan, available from Quality Resources, One Water Street, White

Plains NY.

Acord, (1997) T AcordThe importance of product designFurniture

Design and Manufacturing, 69 (1)

(1997), pp. 90–93

Reilly, Norman B, The Team based product development

guidebook, ASQ Quality Press, Milwaukee

Wisconsin, 1999

Sullivan, L.P., 1986, "Quality Function

Deployment", Quality Progress, June, pp 39-50.

No comments:

Post a Comment